Unmanned Aerial Vehicles (UAVs) commonly known as drones are rapidly transforming the global mining industry. Once associated mainly with military and recreational use, UAVs have become indispensable tools for modern mining operations, enabling faster decision-making, improved safety, reduced costs, and stronger environmental compliance. As mining companies accelerate their transition toward Mining 4.0, drones are no longer optional. They are a strategic necessity. This pillar article examines how UAV technology is reshaping mining operations, the leading drone companies driving innovation, and what this transformation means for mining companies particularly in emerging markets such as Africa.

The Rise of UAVs in the Mining Industry

Mining has traditionally relied on heavy machinery, manual surveying, and time-consuming site inspections. These methods, while effective, are often costly, slow, and risky. UAVs have disrupted this model by providing high-resolution aerial imagery, real-time mapping, and volumetric analysis at a fraction of the time and risk.

Drone adoption in mining is accelerating rapidly. Industry analysts project the mining UAV market to grow at a compound annual growth rate (CAGR) exceeding 20% through 2030, driven by automation, demand for real-time operational data, and stricter safety and environmental regulations.

From open-pit mines in Africa to underground operations in North America and Australia, UAVs are now central to exploration, production, and mine closure planning.

Key Applications of UAVs in Mining Operations

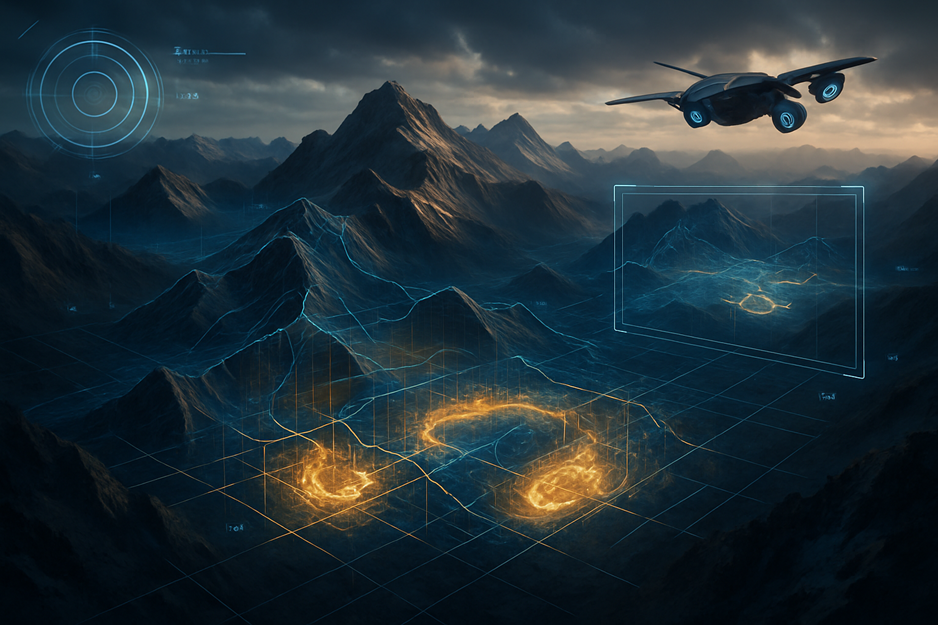

1. Surveying, Mapping, and Digital Twins

UAVs equipped with LiDAR sensors and photogrammetry cameras can generate highly accurate 3D terrain models and digital twins of mining sites. What once took weeks of ground-based surveying can now be completed in hours.

These datasets are essential for:

- Pit and blast design

- Haul road optimization

- Mine expansion planning

- Environmental baseline studies

The integration of drone data with GIS and mine planning software allows operators to visualize operations in real time and make data-driven decisions.

2. Safety and Risk Management

Mining remains one of the world’s most hazardous industries. UAVs significantly reduce risk by eliminating the need for personnel to enter dangerous areas such as:

- Unstable pit walls

- Highwalls and tailings dams

- Confined underground stopes

Real-time aerial video and thermal imaging enable early detection of geotechnical risks, equipment malfunctions, and unauthorized site access. This proactive approach has been shown to reduce workplace accidents and improve regulatory compliance.

3. Stockpile Measurement and Inventory Control

Accurate stockpile measurement is critical for operational efficiency and financial reporting. UAVs deliver precise volumetric calculations of:

- Ore stockpiles

- Waste rock

- Processed materials

Drone-based measurements reduce human error, improve reconciliation accuracy, and support transparent reporting to investors and regulators.

4. Environmental Monitoring and Compliance

Environmental stewardship is now a core requirement for mining companies. UAVs equipped with multispectral and thermal sensors support continuous monitoring of:

- Dust emissions

- Water quality and drainage patterns

- Vegetation health

- Land disturbance and rehabilitation progress

Early identification of environmental risks allows mining companies to address issues before they escalate, strengthening relationships with regulators, communities, and ESG-focused investors.

5. Operational Oversight and Productivity Optimization

Beyond surveying, UAVs enhance day-to-day mine management by enabling:

- Equipment tracking

- Road condition monitoring

- Production rate analysis

- Predictive maintenance planning

When integrated with enterprise mine management systems, drone data supports operational optimization, cost control, and long-term strategic planning.

Leading UAV Companies Powering the Mining Sector

Several global technology companies have emerged as leaders in mining-focused UAV solutions:

DJI (Dà-Jiang Innovations)

DJI is the world’s largest UAV manufacturer and a dominant player in mining applications. Platforms such as the Matrice and Phantom series are widely used for aerial mapping, inspections, and volumetric analysis due to their reliability and sensor compatibility.

senseFly (Parrot Group)

senseFly specializes in fixed-wing UAVs designed for large-scale surveying. The eBee series is optimized for long-endurance flights and high-accuracy geospatial data capture, making it ideal for expansive mine sites.

Delair

Delair offers industrial-grade UAVs with extended flight times and seamless integration with GIS platforms. Their solutions are commonly deployed for operational monitoring and environmental compliance.

Kespry

Kespry provides an end-to-end drone ecosystem combining UAV hardware with cloud-based analytics. Its automated workflows are particularly popular for stockpile measurement and site planning in mining operations.

Trimble Inc.

Trimble integrates UAV platforms with advanced GNSS and geospatial software, delivering highly accurate 3D modeling and digital twin solutions for mine planning and resource management.

Other notable providers include Terra Drone, Quantum Systems, Microdrones, and Flyability, each offering specialized capabilities such as underground inspection, LiDAR mapping, and long-range surveys.

The Impact of UAV Adoption on the Mining Industry

The integration of UAV technology has delivered measurable benefits across the mining value chain:

- Efficiency Gains: Surveys and inspections completed in hours instead of weeks

- Cost Reduction: Lower labor costs and reduced downtime

- Improved Safety: Less human exposure to hazardous environments

- Environmental Assurance: Continuous, auditable compliance monitoring

- Better Decision-Making: Real-time data supports predictive and strategic planning

Together, these benefits are reshaping mining into a more resilient, transparent, and technology-driven industry.

UAVs and Mining in Africa: A Strategic Opportunity

In Africa, where mining plays a critical role in economic development, UAV adoption is gaining momentum. Drones offer cost-effective solutions for:

- Remote site monitoring

- Rapid exploration surveys

- Regulatory reporting

- Community and environmental oversight

For countries like Ghana, UAVs align closely with national objectives around mineral transparency, safety, and sustainable mining practices. As regulatory frameworks mature, drone technology is expected to become standard across both large-scale and mid-tier mining operations.

The Future of UAVs in Mining

The next phase of UAV adoption will be defined by:

- AI-powered image analysis

- Autonomous flight planning

- Predictive analytics

- Full integration with mine automation systems

As these capabilities mature, drones will evolve from data collection tools into intelligent decision-support systems, reinforcing their role at the core of modern mining operations.

Conclusion

UAVs are fundamentally changing how mines are planned, operated, and monitored. By delivering real-time, high-precision data while improving safety and environmental performance, drone technology has become a cornerstone of modern mining.

For mining companies seeking to remain competitive, compliant, and sustainable, UAV adoption is no longer a choice, it is a strategic imperative.

3 thoughts on “UAVs in Mining: How Drone Technology Is Transforming Safety, Surveying, and Operational Efficiency”